- We work with global industries!

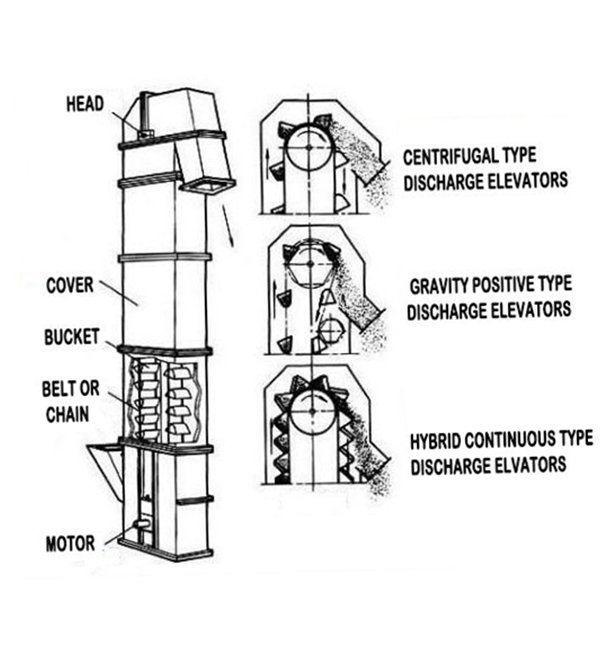

Centrifugal Bucket Elevator Is the most common type, as the design is the most economical. A centrifugal bucket elevator operates by rotating at a rapid pace which causes material to be discharged at the top of the elevator via centrifugal force. Elevator runs at a high speed of about 1.3 m/sec. and the material is thrown out by centrifugal force. They are meant for use with fine granular material because the speed of rotation is too quick for lumpy materials.

Continuous Bucket Elevator These Bucket Elevators are necessary when the material conveyed is to be handled carefully and not damaged in anyway during handling. These elevators also normally operate at a slow speed of about 0.6 m/sec.They are used to handle finely composed materials, or light fluffy material which must not be aerated. Continuous bucket elevators are fed by direct flow only.There are virtually no gaps between buckets to prevent material from spilling out and to increase the amount of material being processed per rotation.Continuous bucket elevators are gentler than centrifugal bucket elevators because they operate at lower speeds.

Positive Discharge Bucket Elevator These elevators are used where the material is either sticky or light and fluffy. The buckets after passing over the head sprocket are inverted over the idler sprocket, thus providing a positive discharge of material. Further as the buckets are to be inverted over the idler sprocket, these bucket elevators have to be of double chain design, as the bucket are held in between two chains.The buckets after passing over the head sprocket are inverted over the idler sprocket, thus providing a positive discharge of material. The speeds for this elevator are lower at about 0.6 m/sec.